TotalBoat TableTop Epoxy is an easy-to-use pourable epoxy system for clear coating bar tops, tables, counters & more with a clear, glassy finish that protects and preserves the surface underneath. Self-leveling, 100% waterproof system creates a maintenance-free durable finish that resists scratching, staining & yellowing. BPA-free formula contains no VOCs. All ingredients are on the USDA approved list for contact with food, once cured.

TableTop has a simple 1 to 1 mix ratio and cures at room temperature. Easy to mix and apply, it's a great choice for pros and DIYers alike. Cures blush-free and won't distort with age. In extensive testing, its finish clarity met or exceeded all similar products on the market. Compare to System Three MirrorCoat.

Available in 2 QT, 1 GAL, 2 GAL and 4 GAL sizes.

Note: TableTop Epoxy is also available in a 110 gallon kit consisting of 55 gallons of resin and 55 gallons of hardener. Please contact us for pricing.

| HANDLING PROPERTIES | VALUE | TEST METHOD |

|---|---|---|

| Resin Density at 77°F, lbs/gal | 9.7 | ASTM D1475 |

| Hardener Density at 77°F, lbs/gal | 8.1 | ASTM D1475 |

| Resin Viscosity at 77°F, cP | 9,000 | ASTM D2196 |

| Hardener Viscosity at 77°F, cP | 2,000 | ASTM D2196 |

| Viscosity Mixed at 77°F, cP | 3,500 | ASTM D2196 |

| Mix Ratio by Volume | 1A:1B | Calculated |

| Mix Ratio by Weight | 100A:83B | Calculated |

| Gel Time at 77°F, 150 gram mass, min | 30 | ASTM D2471 |

| PHYSICAL PROPERTIES | VALUE | TEST METHOD |

|---|---|---|

| Color | Clear | Visual |

| Hardness, Shore D | 82 | ASTM D2240 |

| Tensile Strength, psi | 7,500 | ASTM D638 |

| Tensile Elongation, % | 5.9 | ASTM D638 |

| Tensile Modulus, psi | 382,000 | ASTM D638 |

| Compressive Strength, psi | 10,400 | ASTM D695 |

| Flexural Strength, psi | 12,800 | ASTM D790 |

| Flexural Modulus, psi | 373,000 | ASTM D790 |

| HDT, Room Temp. Cure, F | 120 | ASTM D648 |

| HDT, Post Cure, F | 130 | ASTM D256 |

| Izod Impact, Notched, ft-lb/in | 0.76 | ASTM D256 |

| Technical Specifications | TotalBoat TableTop Epoxy |

|---|---|

| Maximum Pour Depth, Per Layer | 1/8'' - 1/4'' |

| Full Cure Time | 3-5 days |

- Simple Instructions for Using TotalBoat TableTop Epoxy

- Multiple, thin pours are recommended, rather than one thick flood coat, because a thick coat can trap air bubbles beneath the surface, and generate excessive heat, which will distort the surface, resulting in an improper cure.

- Do not place items hotter than 125°F on the cured surface, or it will discolor and become distorted.

- Faster cure time for coating and shallow-depth embedding projects

- Simpler 1:1 mix ratio (ThickSet is 3:1)

- Requires fewer pours to achieve final thickness of 1/2" and more

- Reduces possibility of banding (ability to see individual layers)

- Gives you longer working time at room temperature

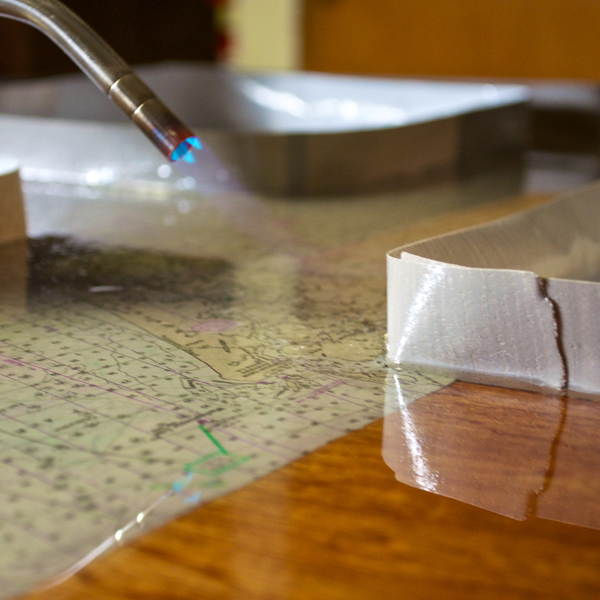

Taping the Edges: To contain the liquid epoxy, apply plastic packing tape around the edges of the table. Plastic packing tape is best because it releases easily & cleanly after the epoxy is cured.

Mixing: For best results, use the "2-cup mixing method": Add resin and hardener to the first mixing cup at a 1 to 1 ratio by volume. Stir for 3-5 minutes, then transfer the mixture to a second mixing cup and continue stirring until blended thoroughly. Be sure to use clean tools for mixing and application.

Temperature & Application: Warm conditions are critical for success. For best results, only apply in temperatures between 70-80°F. First, apply a thin seal coat to the surface. After the seal coat has set, apply additional flood coats, up to 1/8" thick. Wait 4-8 hours between each flood coat.

Leveling Tips: Flood coats will self-level but epoxy spreaders and brushes can be used to spread it over the surface.

Recoating: Additional coats may be applied after 4 to 8 hours without sanding or additional prep work. However, if the previous coat cures fully, scuff sand with 220-320 grit sandpaper before applying another coat. After sanding, wipe down with acetone or denatured alcohol to remove sanding dust and let dry before applying an additional coat. Sanding between coats will not adversely affect the cosmetics of the final product—the hazy surface will become clear when the next flood coat is applied.

IMPORTANT!

Should I Use TotalBoat TableTop Epoxy or TotalBoat ThickSet Epoxy?

Both of these professional quality epoxies give you beautiful results for crystal-clear coating, casting, encapsulating or embedding projects. However, TotalBoat TableTop Epoxy is more of a 'coating' epoxy, and TotalBoat ThickSet epoxy, is more of a 'casting' epoxy designed for thicker pours.

TotalBoat TableTop Epoxy Advantages

The maximum single-layer depth for TotalBoat TableTop Epoxy is 1/8"-1/4".

TotalBoat ThickSet Epoxy Advantages

Designed for thick casting, ThickSet allows you to do deeper single-layer pours than you can do with TotalBoat TableTop Epoxy. For example, you can pour a single layer of TotalBoat ThickSet 1/2"-1" deep when pouring into large areas or molds, and up to 2" deep when pouring into small molds.

*UV resistant formula, not intended for outdoor applications with prolonged exposure to sunlight.

Technical Information

Features and Specifications:

- Unique 2-part, high-viscosity epoxy system cures at room temperature.

- Easy to use 1 to 1 mix ratio, cures to a clear and deep, glass-like finish.

- 100% waterproof. Resists scratches, stains, and yellowing.

- *UV resistant formula, not intended for outdoor applications with prolonged exposure to sunlight.

- Formula provides superior results on bar tops and table tops.

- BPA-Free formula contains NO VOCs, making Tabletop a safer alternative to use and once cured, especially for food contact

- All ingredients are listed on the USDA approved list for contact with food, once TotalBoat TableTop Epoxy has cured completely.

- Great for wood or art projects like embedding objects, decoupage and other crafts.

- Ideal for DIYers and professionals alike.

- Available in 2 Quart, 1 Gallon, and 2 Gallon Kits:

- 2 Quart Kit contains 1 quart of resin & 1 quart of hardener

- 1 Gallon Kit contains 1/2 gallon of resin and 1/2 gallon of hardener

- 2 Gallon Kit contains 1 gallon of resin and 1 gallon of hardener

- Compare to System Three MirrorCoat Epoxy.

- Coverage is typically 25.6 sq. ft. for the 2 Gallon Kit, at 1/8" thick; 12.8 sq. ft. for the 1 Gallon Kit, at 1/8" thick; 6.4 sq. ft., at 1/8" thick for the 2 Quart Kit.

How to use TotalBoat TableTop Epoxy:

- Mix resin and hardener (1:1 ratio) in a mixing cup.

- Pour out epoxy in an S shape onto the surface. When pouring, fill the lowest part first.

- Spread with foam brush or plastic epoxy spreader.

- Let sit for 5 minutes.

- Move a propane torch or heat tool 6 inches above the surface. Going back and forth across the surface will eliminate air bubbles. Do not leave the torch on one area or it will burn & distort the epoxy

- Allow epoxy to cure.

Maximum Pour Depth, Per Layer, for TotalBoat TableTop Epoxy

- 1/8'' - 1/4''

Recommended Products

Reviews for TotalBoat TableTop Epoxy

Verified Purchase

This epoxy is exactly what I was looking for and did the job exactly as expected. Super clear and made my projects pop and the price is crazy. Extremely affordable, easy to use and clean up afterwards. Will be ordering from Total Boat going forward.

Was this review helpful to you?

Verified Purchase

When my customer wants a hole filled in epoxy resin or a river running through a table top, I always reach for Totalboat table top epoxy resin. It mixing well together and with color pigments. I am very happy with this product and my customers are too.

Was this review helpful to you?

Verified Purchase

Getting it mixed compared to some of the "cheaper" epoxies I've tried is like the difference between room temperature and cold honey. It loosens up with mixing and coloring agents, but it does seem to produce a better product and a little less bubbles, however you need a little extra vigilance as the bubbles do rise later than the other epoxies I've used. For those who do small projects like myself, smaller squeeze bottles like ketchup bottles, must be tight caps, do wonders instead of pouring from a large bottle and almost eliminate drips. Non pro tip right there.

Was this review helpful to you?

Verified Purchase

The product is okay. The microscopic instructions made things somewhat difficult. There's plenty of room to use a larger font. The instructions and those that I got from tech support were terrible and just plain wrong. The room, at 75 ,reduces the working time to about ten minutes. The method for coating a rolled edge was altogether wrong. Thank heavens for YouTube.

Was this review helpful to you?

Verified Purchase

I love using this product! I always buy it over and over everytime I'm almost done with each bottle. I make all my pieces with this resin and always comes out great.

Was this review helpful to you?

Verified Purchase

Absolutely simple to work with and excellent results

Was this review helpful to you?

Verified Purchase

I frequently buy this epoxy. Consistently delivers beautiful waves that I use for my epoxy resin boards. Always timely shipping and the BEST customer service team hands down.

Was this review helpful to you?

Verified Purchase

I'm an ocean resin artist and this is the only resin I use to get the most beautiful waves and flawless shine!

Was this review helpful to you?

Verified Purchase

This is so easy to mix and work with even though you have 20 minutes from the start of mixing the epoxy and hardener together. I did a countertop for my dad's kitchen and it turned out FLAWLESSLY!

Was this review helpful to you?

Verified Purchase

Using your help line I got detailed advice on product selection and application tips

Was this review helpful to you?