TotalBoat Traditional 5:1 Epoxy Resin is suitable for a wide range of boatbuilding and repair projects. This versatile epoxy resin is designed for use with our TotalBoat Fast, Slow, Tropical, and Crystal Clear Hardeners, but is also 100% compatible with all leading traditional marine 5:1 epoxy systems.

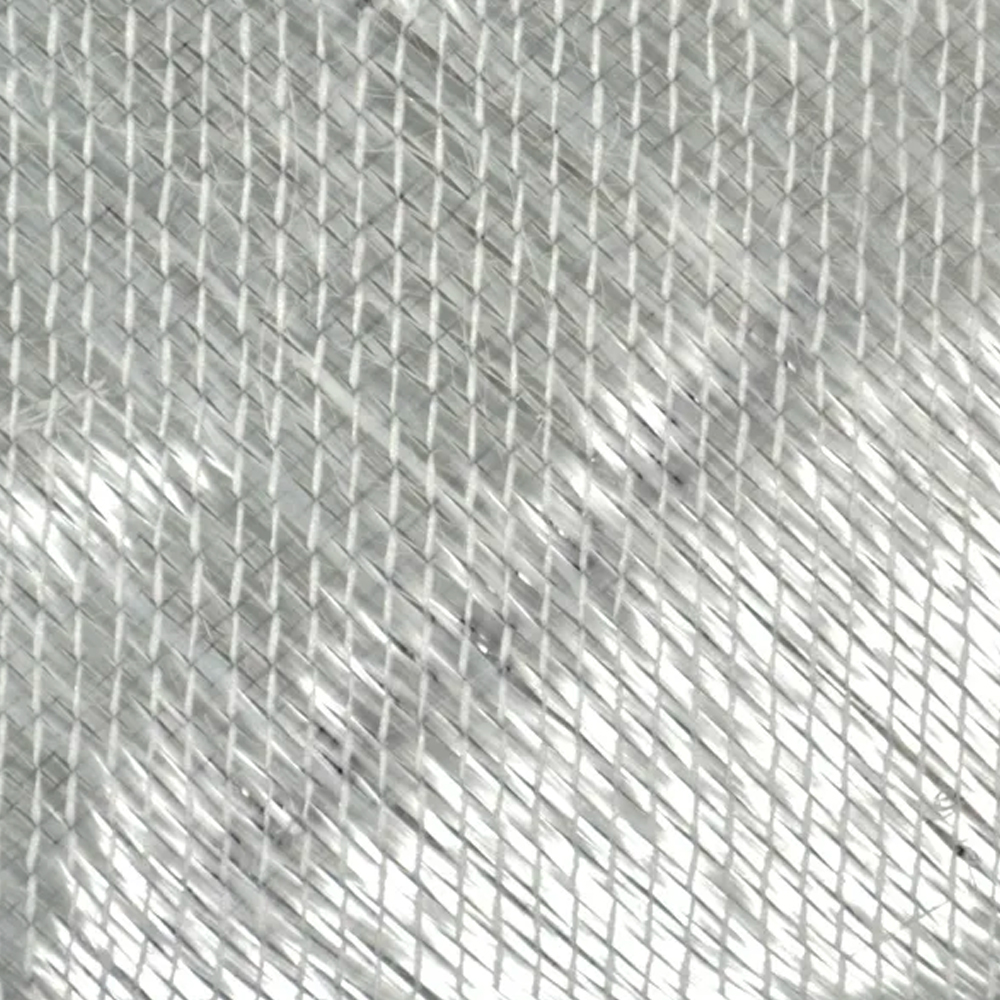

Traditional epoxy resin bonds with fiberglass, reinforcing fabrics, wood, and metals. When combined with any additional fillers, TotalBoat resin creates an excellent adhesive, filleting, and fairing compound. It cures to a high-strength, plastic solid with excellent moisture resistance. Once cured, it can be sanded and shaped.

Wets-out and bonds easily with fiberglass & other fabrics. It has excellent thin-film characteristics to easily flow out and self-level, making any laminating job easy.

Includes Resin ONLY. Hardeners must be purchased separately.

Note: TotalBoat 5:1 epoxy is also available in a 55 gallon drum, along with corresponding sizes of Fast and Slow hardeners. Please contact us for pricing.

| Properties (Admixed) | Fast Hardener | Slow Hardener | Tropical Extra Slow Hardener |

|---|---|---|---|

| Color | Clear Amber | Clear Amber | Clear Amber |

| Mix Ratio by Volume (Resin:Hardener) | 5:1 | 5:1 | 3:1 |

| Mix Ratio by Weight (Resin:Hardener) | 100:18 | 100:18 | 100:28 |

| Pot Life at 75°F | 12 min. | 20 min. | 46 min. |

| Work Life at 75°F (Thin Film) | 60 min. | 90 min. | 3-4 hrs. |

| Set Time at 75°F (Thin Film) | 6 hrs. | 10 hrs. | 20-24 hrs. |

| Cure Time at 75°F (Thin Film) | 1-4 days | 1-4 days | 4-7 days |

| Minimum Recommended Temperature | 40°F | 60°F | 70°F |

| Tensile Strength | 8,000 psi | 7,500 psi | 6,800 psi |

| Tensile Modulus | 410,000 psi | 460,000 psi | 390,000 psi |

| Tensile Elongation | 3.5% | 4.5% | 6.6% |

| Flexural Strength | 14,400 psi | 12,000 psi | 13,800 psi |

| Flexural Modulus | 460,000 psi | 450,000 psi | 406,000 psi |

| Compressive Strength | 11,500 psi | 11,500 psi | 11,900 psi |

| Hardness, Shore D | 84 | 83 | 85 |

| Intended for Clear Coating Applications? | NO | NO | NO |

- TotalBoat Traditional Epoxy Resin can be combined with any of our TotalBoat Hardeners (Fast, Slow, or Tropical Extra Slow) for exceptional results.

- Use the TotalBoat 5:1 Epoxy Pump Set when using TotalBoat Traditional Epoxy Resin with:

- TotalBoat 5:1 Fast Hardener

- TotalBoat 5:1 Slow Hardener

- Use the TotalBoat 3:1 Epoxy Pump Set when using TotalBoat Traditional Epoxy Resin with:

- TotalBoat Tropical Extra Slow Hardener

TotalBoat epoxy resin and hardeners are packaged and labeled according to group sizes (A, B, C) to ensure you have enough material for your project at the best value.

Clear-coating applications: The Traditional Epoxy Resin itself is clear, but when mixed with Fast, Slow, or Tropical Extra Slow Hardeners, it's amber in color and is not suitable for clear-coating applications.

TotalBoat epoxy resin and hardeners can be measured either by pouring or by using the calibrated TotalBoat pumps. TotalBoat dispensing pumps are specific to the type of TotalBoat Hardener you are using with TotalBoat Traditional Epoxy Resin (see details below).

For your safety, please be sure to wear protective gloves and eye, face, and clothing protection when working with epoxy resin and hardeners. Also, be sure your work area has adequate ventilation.

USING THE TOTALBOAT PUMPS FOR DISPENSING TOTALBOAT RESIN AND HARDENER

The procedure for dispensing TotalBoat Traditional Epoxy Resin and any of the TotalBoat Hardeners properly is ALWAYS ONE full pump of resin to ONE full pump of hardener. TotalBoat pump sets are calibrated to dispense the accurate mix ratio automatically.IMPORTANT! Proper mix ratios are critical when working with epoxy resin and hardeners in order to achieve a proper cure.

★ TotalBoat Traditional Epoxy Resin used with either TotalBoat Fast Hardener or TotalBoat Slow Hardener are mixed at a ratio of 5 parts resin to 1 part hardener by volume.

★ TotalBoat Traditional Epoxy Resin can be used with TotalBoat Tropical Hardener mixed at a ratio of 3 parts resin to 1 part hardener by volume.

TotalBoat Epoxy Pump Sets are specific to the type of TotalBoat Hardener you are using with TotalBoat Traditional Epoxy Resin. The pumps are calibrated to dispense the proper mix ratio automatically.

Remember, the procedure for dispensing TotalBoat Traditional Epoxy Resin and Hardener properly is always ONE full pump of resin to ONE full pump of hardener.

When using the pump dispensing method for measuring TotalBoat Traditional Epoxy Resin and TotalBoat Fast Hardener or TotalBoat Slow Hardener, use ONLY the TotalBoat 5:1 Epoxy Pump Set. The TotalBoat 5:1 pumps are calibrated to dispense the accurate 5:1 mix ratio automatically. DO NOT use pumps from any other manufacturer; DO NOT use the TotalBoat 3:1 Epoxy Pump Set.

Remember, the procedure for dispensing TotalBoat Traditional Epoxy Resin and Hardener properly is always ONE full pump of resin to ONE full pump of hardener.

When using the pump dispensing method for measuring TotalBoat Traditional Epoxy Resin and TotalBoat Tropical Hardener, use ONLY the TotalBoat 3:1 Epoxy Pump Set. The TotalBoat 3:1 pumps are calibrated to dispense the accurate 3:1 mix ratio automatically. DO NOT use pumps from any other manufacturer; DO NOT use the TotalBoat 5:1 Epoxy Pump Set.

NOTE: Adding more hardener does not make the epoxy set faster. It throws off the mix ratio and will not cure properly.

PRIME THE RESIN AND HARDENER PUMPS BEFORE DISPENSING

Push down and release the head of each pump several times until you get a steady stream of liquid without any air pockets.COLD WEATHER OPERATION: Cold temperatures make the viscosity of resin and hardeners increase and may require more force to pump thicker materials. Excessive force on either one of the plunger heads however, may also cause the pumps to break. Dispensing material in 60-70°F is recommended for optimal pump performance.

In cooler temperatures, warming the containers prior to pumping will decrease the epoxy viscosity, making materials pump more easily.

MIXING

After dispensing resin and hardener into a plastic mixing pot, use a wooden stir stick to mix thoroughly.Tip: Wash cured epoxy with water, scrubbing lightly with a Scotch-Brite pad to remove any amine blush prior to overcoating or painting.

Technical Information

Group Size A

- TotalBoat Traditional Epoxy Resin - 1 Quart

- TotalBoat Fast Hardener - 6 oz.

- TotalBoat Slow Hardener - 6 oz.

- TotalBoat Extra Slow Tropical Hardener - 10 oz.

Group Size B

- TotalBoat Traditional Epoxy Resin - 1 Gallon

- TotalBoat Fast Hardener - 25 oz.

- TotalBoat Slow Hardener - 25 oz.

- TotalBoat Extra Slow Tropical Hardener - 42.3 oz.

Group Size C

- TotalBoat Traditional Epoxy Resin - 4.46 Gallons

- TotalBoat Fast Hardener - 127 oz.

- TotalBoat Slow Hardener - 127 oz.

- TotalBoat Extra Slow Tropical Hardener - n/a

Important Safety Information

Always wear protective clothing and equipment to protect your eyes, skin, and lungs when working with TotalBoat Traditional Epoxy Resin and Hardeners. Personal protective clothing should include appropriate gloves, safety glasses or goggles, a proper respirator, and a proper apron or similar protective clothing.

Recommended Products

Reviews for TotalBoat Traditional 5:1 Epoxy Resin

Verified Purchase

Worked great, but feel the hardner could have consisted of more for the price!

Was this review helpful to you?

Verified Purchase

Using the slow hardener, I had plenty of time to work before hardening set in. It flows nicely when wetting the glass.

Was this review helpful to you?

Verified Purchase

Worked great on coasters I made. It was a deep pour.

Was this review helpful to you?

Verified Purchase

This was a small order of resin only. When I opened the package there were 8 color packages. I went to the JD website but couldn't find any information about how to mix them. JD should add a section about this.

Was this review helpful to you?

I wanted to use an indoor wood coffee table outside in covered patio area. Had no idea what I was doing but followed instructions and watched a few videos and the table turned out great. Going on a year outside with no problems at all. It did take longer to cure than I thought it should but likely just my lack of experience with epoxy.

Was this review helpful to you?

Verified Purchase

Great Product. Easy to use, and the dispensers work well.

Was this review helpful to you?

Verified Purchase

I use this resin for various repairs and project both on the boat and around my ancient house. It works great.

Was this review helpful to you?

Verified Purchase

I have had very good sucess with Total Boat product's.

Was this review helpful to you?

Verified Purchase

Great products good shipping times reasonable prices

Was this review helpful to you?

Verified Purchase

I will try a different product next time

Was this review helpful to you?