- Home

- / Paints

- / Bottom Paint

Interlux VC-17m is a thin-film antifouling paint for boats used fresh water, brackish, and low-fouling cold salt waters. Unique ultra-thin formula is nearly eight times thinner than conventional boat bottom paints, creating a finish that reduces weight and drag. Get an ultra smooth, burnished finish without sanding, and go faster with VC-17m!

This paint has a long history of use on racing sailboats. Powerboat owners choose it for improved fuel efficiency and the peace of mind that higher speeds won't wear away the paint, unlike most ablatives. Thin film paint also means no paint build up and no heavy sanding the following season. A special flouro additive with cuprous oxide (copper) powder ensures reliable protection against barnacles, zebra mussels, algae, and slime. Fast drying formula lets you re-launch quickly.

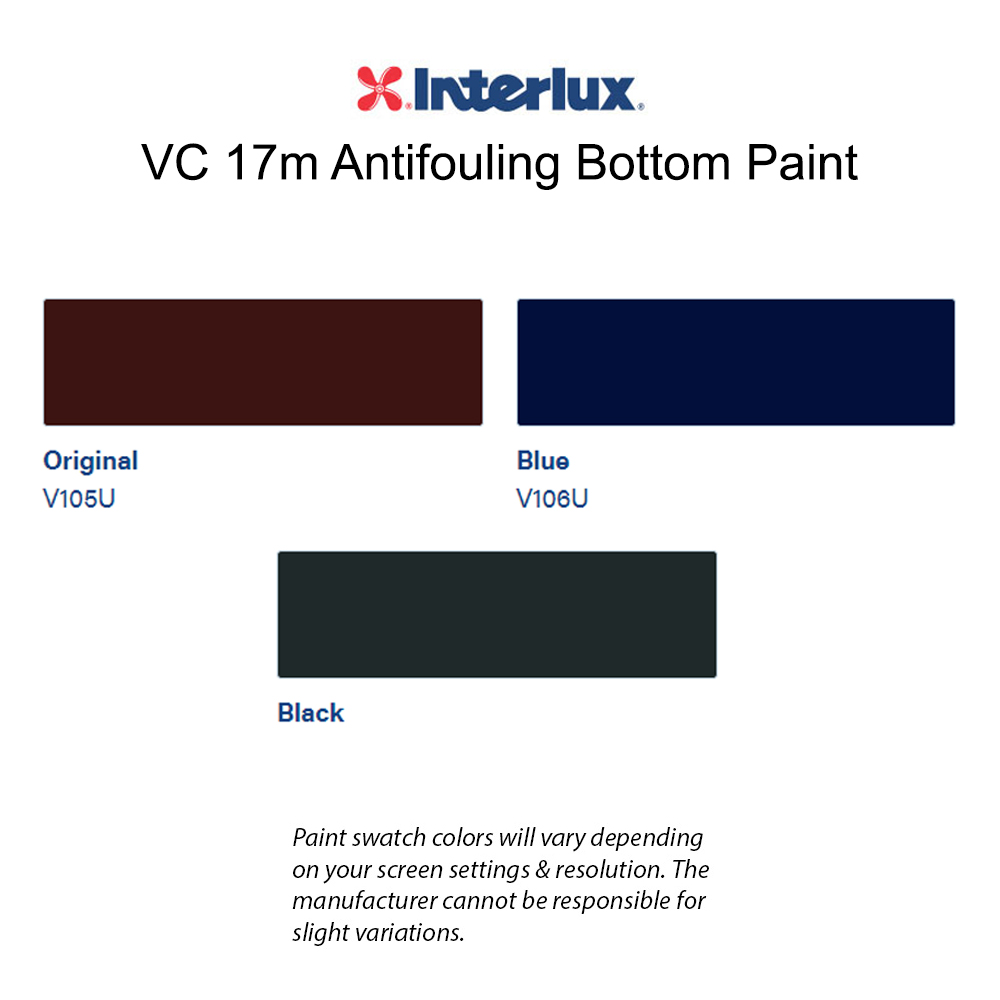

Available in Original, Black, and Blue in Quart size.

Not for use in California or Indiana

REBATE: 2023 Interlux Spring Mail-In Rebate Program - see the INFO & GUIDES tab for details!

| Drying Information | 50 Degrees F | 73 Degrees F | 95 Degrees F |

|---|---|---|---|

| Touch dry/Immersion | 5 min/20 min | 3 min/15 min | 2 min/10 min |

| Overcoated By | Min-Max | Min-Max | Min-Max |

| VC 17M | 10 min- | 10 min- | 10 min- |

2023 Interlux Spring Mail-In Rebate Program

Purchase up to two (2) gallons of eligible Interlux antifouling paint or up to two (2) quarts of Cetol® Marine and VC®17m between February 1, 2023, and June 1, 2023, and save with the Interlux manufacturer's mail-in rebate. See the Interlux 2023 Spring Mail-In Rebate form for complete details.

APPLICATION AND USE

Preparation

PREVIOUSLY PAINTED SURFACES with VC 17m Surface must be clean and dry prior to application of VC 17m. Sand areas that are loose or flaking with 320 grade (grit) paper. Clean with Special Thinner 216. Conventional antifouling paints, removals is best but if this is not possible, start sanding with 80 grade (grit) paper and progressively sand with finer grades until the final sanding with 320 grade (grit). Remove sanding residue.

BARE FIBERGLASS It is very important that bare fiberglass be properly prepared to prevent delamination of the antifouling paint. Remove mold release wax using one of the following Interlux products, Fiberglass Surface Prep YMA601 or Fiberglass Solvent Wash 202 following the product label instructions. Fill any surface imperfections with Interlux Watertite following the label instructions. After the surface has been properly prepared follow the application system below. Sand with 320 grade (grit) paper.

BARE WOOD Wipe clean. Sand surface with 120 grade (grit) paper. Wipe clean. Apply VC 17m directly or if a primer is desired apply 4-5 coats of InterProtect 2000E

STEEL/LEAD (Keels & Hulls) Blast to near white metal surface (Sa 2-1/2). Apply 4-5 coats of InterProtect 2000E.

Method Apply 2-3 coats on the area to be coated per season. Do not sand between coats of VC 17m.

Mixing Pour the powder (stored under the plastic hat) into the can. Stir or shake thoroughly.

Thinner Special Thinner 216.

Airless Spray Electric Airless Spray: Pressure: Full. Tip Size: 1.5-1.8 mm/60-70 thou. If spraying in hot, dry conditions or outside with wind, you can add VC 17m Thinner to VC 17m to slow down the dry time during application. Add up to 15% by volume. Spraying too far from the hull will cause dry spraying which will result in poor adhesion and negatively affect the antifouling performance of the product. Spraying of antifouling paints is prohibited in Canada.

Brush Do not brush apply.

Roller Use a short nap (1/8 or 1/4 inch) roller. Add Special Thinner 216 up to 10% should VC 17m be drying too quickly for application. Put just enough paint to fill the roller in the roller tray and put the lid back on the can.

Other Surfaces previously painted with VC 17m do not need to be sanded. Performance of the paint relies directly on the care taken in surface preparation, the application technique, and the number of coats applied. VC 17m is a copper color at application. It is important for performance to ensure that uniform film is achieved and the recommended number of coats are applied.

Sanding When sanding antifouling paint use a vacuum sander that is attached to a properly maintained industrial vacuum with HEPA filters; if hand sanding of antifouling paint is necessary, wet sand only. Wear the proper Personal Protective Equipment. Never burn-off old antifouling paints.

Some Important Points It takes several weeks of immersion to develop final color. It may not change color above the true waterline. Product temperature should be minimum 10 C/50 F and maximum 32 C/90 F. Ambient temperature should be minimum 7 C/45 F and maximum 35 C/95 F. Substrate temperature should be minimum 7 C/45 F and maximum 35 C/95 F.

Compatibility/Substrates Apply to clean, dry, properly prepared surfaces only. Bare surfaces must be sanded. Do not apply VC 17m over graphite antifoulings. Do not apply over soft antifouling paints. Do not apply VC 17m over aluminum.

Number of Coats 2-3

Coverage (Theoretical) - 407.6 (sq ft/Gal)

Recommended DFT 0.3 mils dry

Recommended WFT 4 mils wet

Application Methods Roller, Airless Spray (Electric)

Technical Information

- Color: V105U-Original, V106U-Blue, V107U-Red

- Finish: Matte

- Specific Gravity: 1.024

- Volume Solids: 6.75%

- Mix Ratio: As supplied

- Typical Shelf Life: 2 yrs

- VOC (As Supplied): 737 g/lt

TRANSPORTATION,STORAGE AND SAFETY INFORMATION

TRANSPORTATION: VC 17m should be kept in securely closed containers during transport and storage.

STORAGE: Exposure to air and extremes of temperature should be avoided. For the full shelf life of VC 17m to be realised ensure that between use the container is firmly closed and the temperature is between 5 C/41 F and 35 C/95 F. Keep out of direct sunlight.

DISPOSAL: Container Disposal: Triple Rinse (or equivalent). Then offer for recycling or reconditioning, or puncture and dispose of in a sanitary landfill or by other procedures approved by state or local authorities. Pesticide Disposal: Open dumping is prohibited. Pesticide, spray mixture or rinsate that cannot be used or chemically reprocessed should be disposed of according to procedures approved by Federal, state, or local disposal authorities.

Recommended Products

Reviews for Interlux VC 17m Antifouling Bottom Paint

Verified Purchase

VC17 has been on the bottom since the boat was new in 1983

Was this review helpful to you?

Verified Purchase

I have been using VC 17 over VC tar for many years. Before spring launch I daub a bit of VC Tar over any of the iron keel that has been exposed. I just chip off the rust bubble and cover the spots. If there are a lot of them I may wet-sand just a little. The bottom is pressure washed every fall when hauled. The only other preparation is a wipe down with a rag soaked with a little VC thinner. Then I roll on (with a 2" roller using the VC can cover as a pot) a thinned coat of VC17. That's when I'm glad its a 26' not a 36' boat. But it only takes a couple hours and the surface is OK (not a super-slick race finish - but when I raced I lost more with one rough tack than I ever lose to bad bottom finish). VC 17 keeps the scum loose and easily cleaned in the fall.

Was this review helpful to you?

Verified Purchase

easy application with a 3" form roller, dries very fast (10 min) and make the boat faster then other options. Great for the fresh water lake where we keep our 27' sailboat.

Was this review helpful to you?

I roll it on, but have found the best way to apply to the roller is by putting paint into a squeeze bottle and directly applying it to the roller. Keeps paint from drying in the roller tray, thereby saving paint and money!!!

Was this review helpful to you?

Verified Purchase

This paint is about the only game in town when it comes to maintaining a fresh water racing finish.

Was this review helpful to you?

Verified Purchase

Bottom painting went smoothly and well. Bottom of the boat (at least) looks great

Was this review helpful to you?

Here on Lake Champlain, the Zebra Musscles can ruin your water craft. With a good coating of Interlux VC 17m Extra with Biolux Bottom Coating, the job is a snap. We did not have a single Zebra Musscle on any of our boats.

Was this review helpful to you?

Because this evaporates so quickly - mix it in a two liter soda bottle and have a partner pour a little at a time into your paint roller tray. Finished result looks good and protects well.

Was this review helpful to you?

I have used this for 20 seasons. Goes on easy and works. No bottom paint removal from season to season, just wash and recoat.

Was this review helpful to you?

I've used this for years. It goes on easily with a roller. Makes a smooth, slick surface. Easy to reapply. When it needs to be reapplid, A little light sanding and you are ready for a new coat. Needs to be wiped down occasionally to remove slime and growth but that stuff comes off easily with a swipe of a rag.

Was this review helpful to you?