- Home

- / Paints

- / Bottom Paint

Trilux 33 is Interlux's new tin-free antifouling paint, ideal for aluminum boats, outdrives, and outboards. Use for bright color or bright white finishes on underwater metals.

Based on the latest Biolux technology for improved control of slime and algae growth, it replaces the older Trilux and Micron 33. Use Trilux 33 below the waterline on underwater boat hulls and parts in fresh, salt and brackish water. It can be applied by brush or roller.

While it is specifically formulated for aluminum boats, engines, and drive parts, Trilux 33 works quite well on fiberglass, wood and other underwater metals.

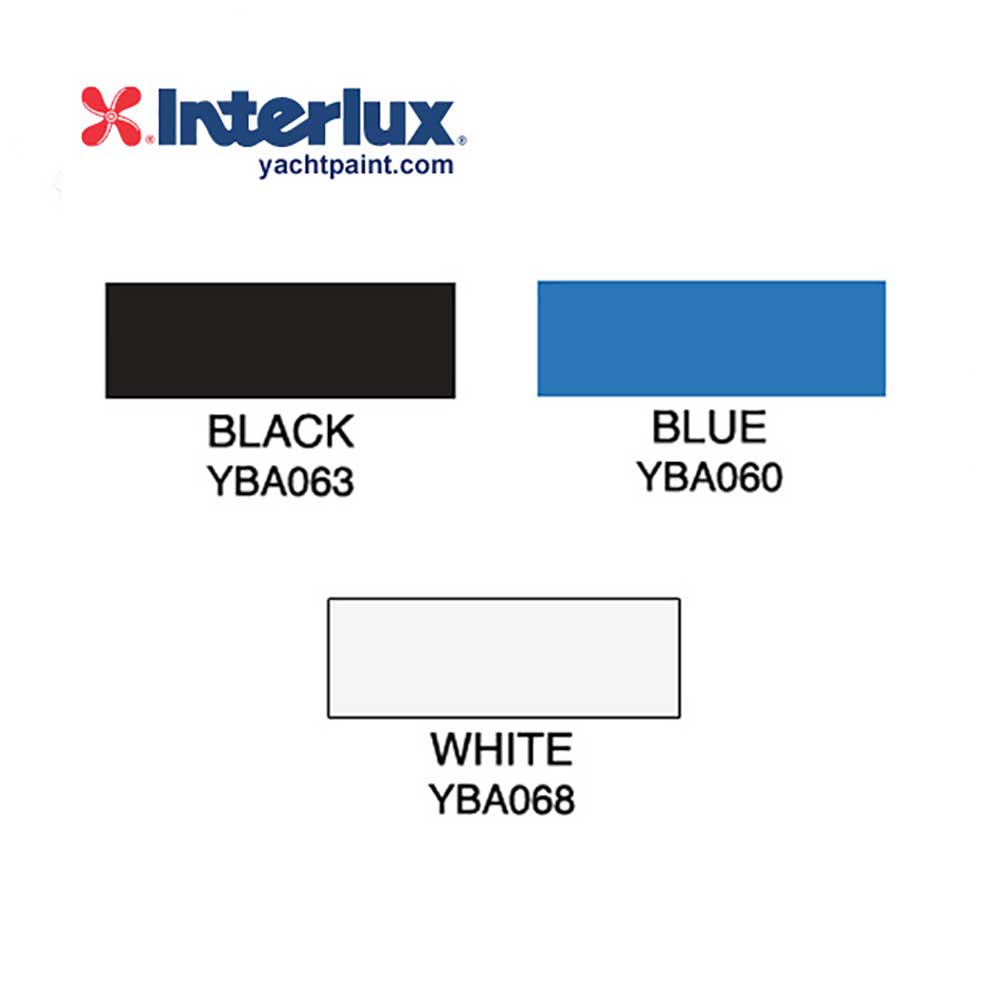

Available in Black, Blue, and White colors in Quart and Gallon sizes. Pint size is available in Black only.

- APPLICATION AND USE

Preparation

BARE ALUMINUM: Sand with medium grade (grit) emery cloth to a bright metal finish. Wipe clean. Apply one very thin coat of Viny-Lux Primewash 353/354. Prime with Interprotect 2000E/2001E. On sandblasted aluminum the Viny-Lux Primewash 353/354 can be omitted if priming with Interprotect the same day as blasting.

FACTORY FINISHED ALUMINUM: Prime with Primocon.

BARE FIBERGLASS: Begin by scrubbing well using soap and water and a stiff brush. Rinse with fresh water. Wipe a small area with a clean rag that has been wetted with Fiberglass Solvent Wash 202. While the surface is still wet, wipe with a clean, dry rag. Continue this process until the entire surface has been cleaned. No Sand System - Apply one thin, continuous coat of Interlux Fiberglass No-Sand Primer. Sanding System - Sand with 80 grade (grit) paper. Remove sanding residue. Wipe with Fiberglass Solvent Wash 202.

BARE WOOD: Sand with 80 grade (grit) paper. Clean with Special Thinner 216. Apply first coat reduced 10% with Special Thinner 216. Fill seams, if necessary, with Seam Compound Brown 30.

EPOXY COATED WOOD: Begin by scrubbing well using soap and water and a stiff brush. Rinse with fresh water. Sand with 120 to 180 grade (grit) paper. Remove sanding residue. Wipe with Fiberglass Solvent Wash 202. Prime with Interprotect 2000E/2001E.

PREVIOUSLY PAINTED SURFACES: with Trilux 33: or Trilux with Biolux: Sand with 80 grade (grit) paper.

OTHER ANTIFOULINGS: Sand surface, wipe clean. Prime with Primocon. Remove antifouling paint in poor condition with Interstrip Semi-Paste 299E.

Method At least 2 coats should be applied.

Hints

Thinner Bare Wood - Special Thinner 216.

Thinning Spray - Special Thinner 216.

Cleaner Bare Fiberglass - Fiberglass Solvent Wash 202. Bare Wood - Special Thinner 216.

Airless Spray Pressure: 170-204 bar/2500-3000 psi. Tip Size: 0.53 mm/21 thou.

Conventional Spray Pressure Pot: Pressure: 3.44-4.47 bar/50-65 psi (gun pressure); 10-15 psi (pot pressure). Tip Size: 1.8-2.2 mm/70-85 thou.

Other Spraying of antifouling paints is prohibited in Canada. To prevent premature failure, ensure correct amount of paint is applied using the coverage as a guide.

Some Important Points Product temperature should be minimum 10 deg C/50 deg F and maximum 29 deg C/85 deg . Ambient temperature should be minimum 10 deg C/50 deg F and maximum 35 deg C/95 deg F. Substrate temperature should be minimum 10 deg C/50 deg F and maximum 29 deg C/85 deg F.

Compatibility/Substrates Apply to clean, dry, properly prepared surfaces only. Surface must be dry and clean, and free from grease, detaching paint etc. Do not apply Trilux 33 directly to aluminum. All metal surfaces must be primed with Interprotect 2000E/2001E or Primocon. Do not apply to tin-based paint such as Micron 33, 44 or Tri-Lux IIT.

Number of Coats 2 Bare Wood: 3 coats (first thinned)

Coverage (Theoretical) - 400 (sq ft/Gal) by brush

Recommended DFT 2.0 mils dry

Recommended WFT 3.9 mils wet

Application Methods Brush, Roller, Airless Spray, Conventional Spray (Pressure Pot) . Spray application is recommended only for Professional Applicators that have all the proper safety equipment including a full-face shield.

Technical Information

- Finish: Low Sheen

- Specific Gravity: 1.3

- Volume Solids: 45%

- Typical Shelf Life: 3 yrs

- VOC (As Supplied): 440 g/lt

- Unit Size: 1 US PINT, 1 US QUART, 1 US GALLON

- Number of Coats: 2 coats, bare wood 3 coats (first thinned)

- Coverage: (Theoretical) - 400 (ft²/Gal) by brush

- Touch Dry Time: 41°F - 8 Hrs, 50°F - 6 Hrs, 73°F - 3 Hrs, 95°F - 2 Hrs

- Immersion Dry Time: 41°F - 36 Hrs, 50°F - 30 Hrs, 73°F - 12 Hrs, 95°F - 10 Hrs

TRANSPORTATION,STORAGE AND SAFETY INFORMATION

TRANSPORTATION:Trilux 33 should be kept in securely closed containers during transport and storage.

STORAGE: Exposure to air and extremes of temperature should be avoided. For the full shelf life of Trilux 33 to be realised ensure that between use the container is firmly closed and the temperature is between 5 deg C/40 deg F and 35 deg C/95 deg F. Keep out of direct sunlight.

DISPOSAL: Container Disposal: Triple Rinse (or equivalent). Then offer for recycling or reconditioning, or puncture and dispose of in a sanitary landfill or by other procedures approved by state or local authorities. Pesticide Disposal: Open dumping is prohibited. Pesticide, spray mixture or rinsate that cannot be used or chemically reprocessed should be disposed of according to procedures approved by Federal, state, or local disposal authorities.

GENERAL: Read the label safety section for Health and Safety Information. Contains biocides. Antifoulings should only be wet sanded. Never dry sand or burn-off old antifoulings. Spraying of antifouling paints is prohibited in Canada.

Recommended Products

Reviews for Interlux Trilux 33 Antifouling Bottom Paint

Verified Purchase

Excellent product, worked and covered as expected. The price was a bit higher here than other suppliers.

Was this review helpful to you?

Verified Purchase

Have used Trilux on my outdrive (pacific northwest), for many years now, and as long as one follows their instructions carefully, and do the proper prepping, it holds up well till I re-do it a year later.

Was this review helpful to you?

Verified Purchase

Does what is expected, which is protect my steel pontoons on a 53 ft houseboat. Great product.

Was this review helpful to you?

I use this on my pontoon boat. My boat is always in the water. Gulf saltwater. I have someone come scrape my boat monthly. I take it out yearly for a thorough cleaning. This stuff works. I still get growth but notice it is a lot less with this.

Was this review helpful to you?

Verified Purchase

Trilux 33 bottom paint is made for aluminum hulls and the red color fits my requirements for my classic Chris Craft Roamer. With 41' x 15' to cover I found it easier to work with if I added a small amount of the Interlux 216 thinner as I worked around the hull. Foam rollers will break down so use a thin nap not made from foam. The new bottom paint can be reapplied over the old paint but should be cleaned of all dried scum with a light sanding or wiping with a cloth drenched with thinner.

Was this review helpful to you?

Use Jamestown's own product for lower units or outdrives. The interlux product is just messy to be around. Gets all over the boat.

Was this review helpful to you?

Verified Purchase

This is the best antifouling paint for aluminum hulls that I have found since they banned the tin formulas. I use an automotive primer over the bare spots then put on the Trilux 33.

Was this review helpful to you?

2/3 the price of any local retailer. Shipping was fast and cheap.

Was this review helpful to you?

This paint protects reasonably well against slime. It is totally useless against barnacle and mussel growth.

Was this review helpful to you?

stay away from the color white. it has a distinct greenish hue to it.

Was this review helpful to you?