- Home

- / Paints

- / Bottom Paint

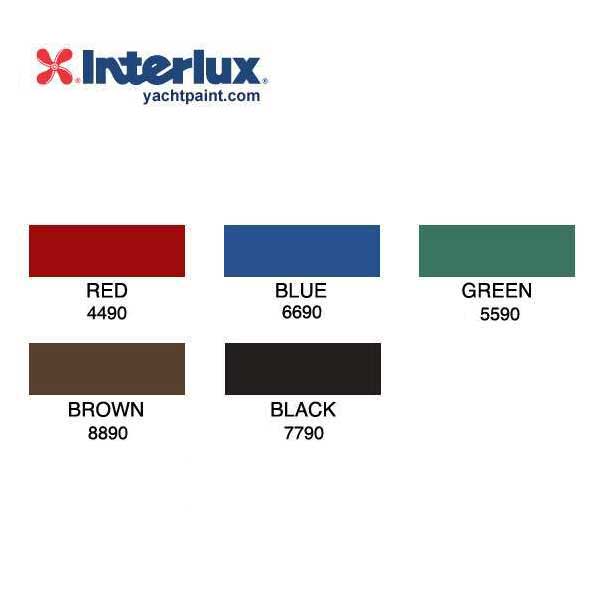

INT-Y7790U/QT -- Quart - Black w/out Irgarol

INT-Y7790U/QT -- Quart - Black w/out Irgarol INT-Y6690U/QT -- Quart - Blue w/out Irgarol

INT-Y6690U/QT -- Quart - Blue w/out Irgarol INT-Y7790U/1 -- Gallon - Black w/out Irgarol

INT-Y7790U/1 -- Gallon - Black w/out Irgarol INT-Y6690U/1 -- Gallon - Blue w/out IrgarolINT-Y8890U/1 -- Gallon - Brown w/out Irgarol

INT-Y6690U/1 -- Gallon - Blue w/out IrgarolINT-Y8890U/1 -- Gallon - Brown w/out Irgarol INT-Y5590U/1 -- Gallon - Green w/out Irgarol

INT-Y5590U/1 -- Gallon - Green w/out Irgarol INT-Y4490U/1 -- Gallon - Red w/out Irgarol

INT-Y4490U/1 -- Gallon - Red w/out Irgarol INT-Y7790U/3 -- 3 Gallon Black w/o Irgarol

INT-Y7790U/3 -- 3 Gallon Black w/o Irgarol INT-6690U3G -- 3-Gallon - Blue w/out Irgarol

INT-6690U3G -- 3-Gallon - Blue w/out IrgarolInterlux ACT bottom paint provides premium seasonal antifouling protection in moderate to heavy fouling areas from algae, slime, barnacles, and zebra mussels. It is compatible with (and can be applied over) other antifouling paint as long as that coating is in acceptable condition.

'ACT' stands for Interlux's Ablative Copolymer Technology, which constantly exposes fresh biocide for anti-fouling protection throughout the season. ACT eliminates the problem of old coating buildup and associated need for heavy sanding to remove. This paint is very effective at controlling shell fouling such as barnacles and zebra mussels, keeping the bottom cleaner longer.

Not for use in California.

REBATE: 2023 Interlux Spring Mail-In Rebate Program - see the INFO & GUIDES tab for details!

| Drying Information | 50 Degrees F | 59 Degrees F | 73 Degrees F | 95 Degrees F |

|---|---|---|---|---|

| Touch Dry (ISO) | 3 hours | 2 hours | 1 hour | 30 min |

| Overcoating Info | Min-Max | Min-Max | Min-Max | Min-Max |

| Time | 16 hours | 14 hours | 12 hours | 8 hours |

2023 Interlux Spring Mail-In Rebate Program

Purchase up to two (2) gallons of eligible Interlux antifouling paint or up to two (2) quarts of Cetol® Marine and VC®17m Extra between February 1, 2023, and June 1, 2023, and save with the Interlux manufacturer's mail-in rebate. See the Interlux 2023 Spring Mail-In Rebate form for complete details.

Note: ACT with Slime Fighter has been retired by Interlux. ACT is still available in the classic formula, but no longer contains Irgarol.

APPLICATION AND USE

Preparation

BARE FIBERGLASS - (POLYESTER OR VINYLESTER): Scrub the surface thoroughly with using a stiff brush and Interlux All Purpose Boat Soap. Rinse with fresh or salt water to remove loose dirt. Flush with fresh water to remove the soap residue and allow to dry. Remove mold release wax using one of the following methods. Apply Fiberglass Surface Prep YMA601 with a maroon, 3M Scotch-BriteTM pad and scrub well. Flush with fresh water or wipe off with a clean, wet cloth ensuring that no traces of Fiberglass Surface Prep remain. An alternative method would be to dampen a cheesecloth with Interlux Fiberglass Solvent Wash 202. Wipe thoroughly to remove all surface contamination and cleaners. Wipe off with a clean, dry rag before liquid dries. To be certain the contamination has been removed, run water over the surface. If the water beads up or separates, repeat one of the above methods. When the water sheets off, all contamination has be removed. Sanding does not remove contamination. After the surface has been properly prepared follow the application system below.

Bare Fiberglass - No Sanding System: Clean surface as above. Apply one thin, continuous coat of Interlux Fiberglass No-Sand Primer with brush or roller (do not spray; do not sand). Follow application guidelines for the primer and apply Fiberglass Bottomkote ACT.

Bare Fiberglass -Sanding System: Clean the surface following the preparation procedure above. Sand with 80 grade (grit) paper and remove sanding residue with Fiberglass Solvent Wash 202. Repair defects with Watertite, then sand and wipe clean. Apply Fiberglass Bottomkote ACT.

BARE WOOD: Sand with 80 grade (grit) sandpaper and remove sanding residue with Special Thinner 216. Repair defects with Watertite, then sand and wipe clean. Apply first coat reduced 10% with Special Thinner 216 or Brush-Ease 433. Fill seams, if necessary, with Seam Compound Brown 30. Apply 2 further coats of Fiberglass Bottomkote ACT.

PREVIOUSLY PAINTED SURFACES: In Good Condition: Wet sand surface with 80 grade (grit) paper to a clean firmly attached surface. Clean with Special Thinner 216. In Poor Condition: Use Interstrip to remove all traces of antifouling. Sand and wipe clean with Fibreglass Solvent Wash 202 for fiberglass and wood substrates. For steel, sandblast or grind to bright metal finish.

STEEL: Contact the Interlux Technical Service Department at 1-800-468-7589 for full information on how to properly prime underwater metals.

Method Apply a minimum of 2 coats (3 on bare wood) by brush, short-nap roller or spray. To prevent premature failure, ensure correct amount of paint is applied using the coverage as a guide.

Hints

Mixing Stir or shake contents thoroughly before use.

Thinner Special Thinner 216 or Brush-Ease 433.

Thinning Thin only if necessary. Thin no more than 10%. Use Brush-Ease 433 if roller or brush drags during application.

Cleaner Painted Surfaces - Special Thinner 216. Bare Fiberglass - Fiberglass Solvent Wash 202 or Fiberglass Surface Prep YMA601. Bare Wood - Special Thinner 216.

Airless Spray Tip Size: 0.53-0.66 mm/21-26 thou. Pressure: 170-204 bar/2500-3000 psi.

Conventional Spray Pressure Pot: Tip Size: 1.8-2.2 mm/70-85 thou. Pressure: 4.08-4.76 bar/60-70 psi (gun pressure); 10-15 psi (pot pressure).

Roller Use a 3/8" nap solvent resistant roller.

Other Take care to apply all the paint calculated even if it means applying an extra coat. Do not apply thin coats. Fill seams if necessary in between 1st and 2nd coats of antifouling with Underwater Seam Compound 30. Spraying of antifouling paints is prohibited in Canada.

Some Important Points Not suitable for use over aluminium/alloy substrates. Colors may fade or change above the waterline. Stir well before use. Product temperature should be minimum 10C/50F and maximum 29C/85F. Ambient temperature should be minimum 10C/50F and maximum 29C/85F. Substrate temperature should be minimum 10C/50F and maximum 29C/85F.

Compatibility/Substrates Not suitable for use over Aluminium/Alloy substrates. Suitable for fiberglass, wood and painted surfaces. Do not apply over tin-based copolymer antifouling paints. Do not use under vinyl based antifouling paints such as VC Offshore, Baltoplate or TBT based antifoulings such as Micron 33.

Number of Coats 2 coats, 3 on bare wood

Coverage (Theoretical) - 455 (sq. ft/Gal)

Recommended DFT 2.0 mils dry

Recommended WFT 3.5 mils wet

Application Methods Brush, Conventional Spray, Roller, Airless Spray

Technical Information

Interlux Fiberglass Bottomkote ACT with Slime Fighter specifications

- Finish: Matte

- Specific Gravity: 2.1

- Volume Solids: 57%

- Typical Shelf Life: 2 yrs

- VOC (As Supplied): 370 g/lt

- Unit Size: 1 US QUART, 1 US GALLON

- Number of Coats:2-3 minimun, Bare Wood- 3 coats (first thinned)

- Coverage:(Theoretical) - 455 (sq. ft./Gal)

- Touch Dry Time: 50 F - 3 Hrs, 73 F - 2 Hrs, 95 F - 1 Hrs

- Immersion Dry Time: 50 F - 16 Hrs, 73 F - 16 Hrs, 95 F - 16 Hrs

TRANSPORTATION, STORAGE AND SAFETY INFORMATION

GENERAL INFORMATION: Exposure to air and extremes of temperature should be avoided. For the full shelf life of Fiberglass Bottomkote® ACT to be realised ensure that between use the container is firmly closed and the temperature is between 5°C/40°F and 35°C/95°F. Keep out of direct sunlight.

TRANSPORTATION: Fiberglass Bottomkote® ACT should be kept in securely closed containers during transport and storage.

GENERAL: Antifoulings should only be wet sanded. Never dry sand or burn-off old antifoulings. Read the label safety section for Health and Safety Information, also available from our Technical Help Line.

DISPOSAL: Do not discard tins or pour paint into water courses, use the facilities provided. It is best to allow paints to harden before disposal. Remainders of Fiberglass Bottomkote® ACT cannot be disposed of through the municipal waste route or dumped without permit. Disposal of remainders must be arranged for in consultation with the authorities.

Recommended Products

Reviews for Interlux ACT Ablative Antifouling Bottom Paint

Packaging looked fine but the gallon container was beat up to the point that won't fit into a shaker. I am assuming that it was that way prior to shipping. I've never had problems in the past with any shipment. This however is frustrating as a customer!

Was this review helpful to you?

Verified Purchase

This is my 3rd season of using ACT, and it holds up really well. Minimal growth with almost zero underwater scrubbing between annual haul outs. A 30 ft Center console uses about 2/3 of a gallon - put on thick. Applies easily.

Was this review helpful to you?

Verified Purchase

Rolled this paint on with 3/8 nap covered nicely.

Was this review helpful to you?

Verified Purchase

Unfortunately I give you NO stars as I did not get FREE shipping and no gown. That was for a my original paint equest you were out of stock. I purchased this one, but as a public service it would have been nice to offer the free shipping and paint gown and roller. It was offered on my original choice. I even had to pay more for this product.

Was this review helpful to you?

Verified Purchase

I've used Interlux ACT for a number of years and it has always performed to specifications. I would caution that it should never be allowed to freeze. It seems that freezing can cause it to become lumpy and or muddy.

Was this review helpful to you?

Verified Purchase

Good product, covererage is great

Was this review helpful to you?

Without biocide this stuff sucks! Did not keep bottom clean for a month!

Was this review helpful to you?

Verified Purchase

I would buy this again

Was this review helpful to you?

Verified Purchase

paint good price right...needs better shipping RE can was banged up causing leakage..

Was this review helpful to you?

I would buy from you again - JD is good to work with.

Was this review helpful to you?