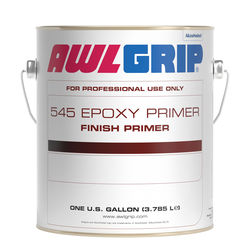

Awlgrip 545 is a two-component epoxy primer system with corrosion and adhesion properties for steel, aluminum, wood, and fiberglass substrates above or below the waterline. This two part system consists of a base and converter, and is used to seal filler primers and fairing work before applying topcoats.

The correct primer for both Awlgrip polyester urethane and AwlCraft 2000 acrlyic urethane topcoats, 545 epoxy primer is available in Gray and White. (Awlgrip D8001, D3001 and D1001 primers). Mix in a 1:1 to 1 1/2 ratio with Converter and apply by spray, brush, or roller.

For Fiberglass: 545 Epoxy Primer Base must be mixed 1:1 by volume with D3001 converter. Spray reduced 15-25% with T0006 Primer Reducer. Brush reduced 0-20% with T0031 Topcoat Brushing Reducer. 2-3 mils (50-75 microns) dry film thickness/2 coats.

- Recoatability: At 77 F/50% relative humidity, Spray: minimum with itself 1 hr, with other products 12 hours. Brush/roll: with itself 12-14 hours, with other products 12-14 hours. Maximum without sanding 24 hours. Sanding is recommended to improve adhesion and appearance.

Overcoat with Awlgrip Awlcraft 2000 Topcoats, High Build Epoxy Primer, AWL-Quick Sanding Surfacer, and Ultra Build Primer.

Application equipment includes conventional spray, airless spray, brush, or roller.

Surface Preparation Aluminum: Sandblast or grind to 100% clean silver color or treat with Alumiprep 33/Alodine 1201/ Steel: Sandblast/grind SSPC-SP5-85 or Sa 2 1/2. Gelcoat/Fiberglass: Sand with 100-150 grit paper. Wood: Smooth sand with 80-100 grit paper.

Mixing and Reduction

Spray: Mix by volume one part 545 base with one part D3001 to a smooth homogenous mixture. Reduce up to 25% with T0006. Overall mix is 1:1 1/2 by volume. Example: 8 oz 545 base, 8 oz D3001, 4 oz T0006.

Brush/Roll: Reduce 5-10% with T0031. Below 75 F you may use Cold Cure Accelerator M3066 to maintain dry and cure times. Anticipated Pot life at 77 F and 50% relative humidity is 16 hours.

Application Instructions

Spray Application: Apply smooth, wet coats to fill and cover surface profile. Two to 3 may be needed at 5 - 6.5 mils WFT yielding 2-3 mils DFT.

Brush and Roller Application Apply 2 coats at 3-4 mils WFT yielding 1.0 - 1.5 DFT per coat. Allow 12-14 hrs between coats. Light sanding between coats will improve appearance. For large surfaces rolling, then tipping with a brush is preferred. Do not apply paint materials to surfaces warmer than 105 F or colder than 55 F. Do not attempt to cure products at temperatures below 55 F.

Warning Do not apply paint materials to surfaces less than 3 C or 5 F above dew point or to surfaces warmer than 41 C or 105 F. Ambient temp should be a minimum 13 C / 55 F and max 41 C or 105 F.

Technical Information

- Coverage: 298 Sq. Feet at one mil dry, 198-496 Sq. Feet at recommended dry film thickness. Coverage calculated for mixed base and converter, reduced 50%.

- Coverage calculations are based on theoretical transfer efficiency of 100%. Actual coverage rate obtained will vary according to equipment choice, application techniques, part size, and application

- Recommended Wet Film Thickness: 7-10 mils (175-250 microns)

- Recommended Dry Film Thickness: 2-3 mils (50-75 microns)

- Recoatability: At 77F/50% R.H. minimum 2-4 hours. Maximum without sanding is 24 hours.

- Plan your work schedule to eliminate having to sand 30-Y-94TM.

- May be overcoated with AWLGRIP/AWLCRAFT 2000 Topcoats, 545 Epoxy Primer, High Build Epoxy Primer, AWL-QUIK Sanding Surfacer, and ULTRA-BUILD Epoxy Primer.

- VOC: White Base 435 g/lt or 3.6 lbs/gal. Gray Base 426 g/lt or 3.6 lbs/gal. Converter 616 g/lt or 5.1 lbs/gal.

- Type: Epoxy Polyamide

- Packaging: 1 Gallon or 1 Quart containers.

Recommended Products

Reviews for Awlgrip 545 Epoxy Primer

Verified Purchase

Used this to prime old whaler. Wish I had bought a gallon.

Was this review helpful to you?

Verified Purchase

Used on 1970 whaler. Probably should have used some high build first but I didn't I just used several coats of the 545. I sprayed it and it looks awesome

Was this review helpful to you?

Verified Purchase

put it on my 53 chevy pickup. went on nice and easy,sands nice very pleased

Was this review helpful to you?

Verified Purchase

Exactly as it should have been delivered. Nothing more to say except that it seems too rare in general these days.

Was this review helpful to you?

Please note: Based on the label of Awlgrip 545 Epoxy Primer, white is not to be used on aluminum. Therefore, use Awlgrip 545 gray Epoxy Primer if you want to protect aluminum.

Was this review helpful to you?

This primer grips substrate like grim death and is great for steel. What can I say about Awlgrip anyway.

Was this review helpful to you?